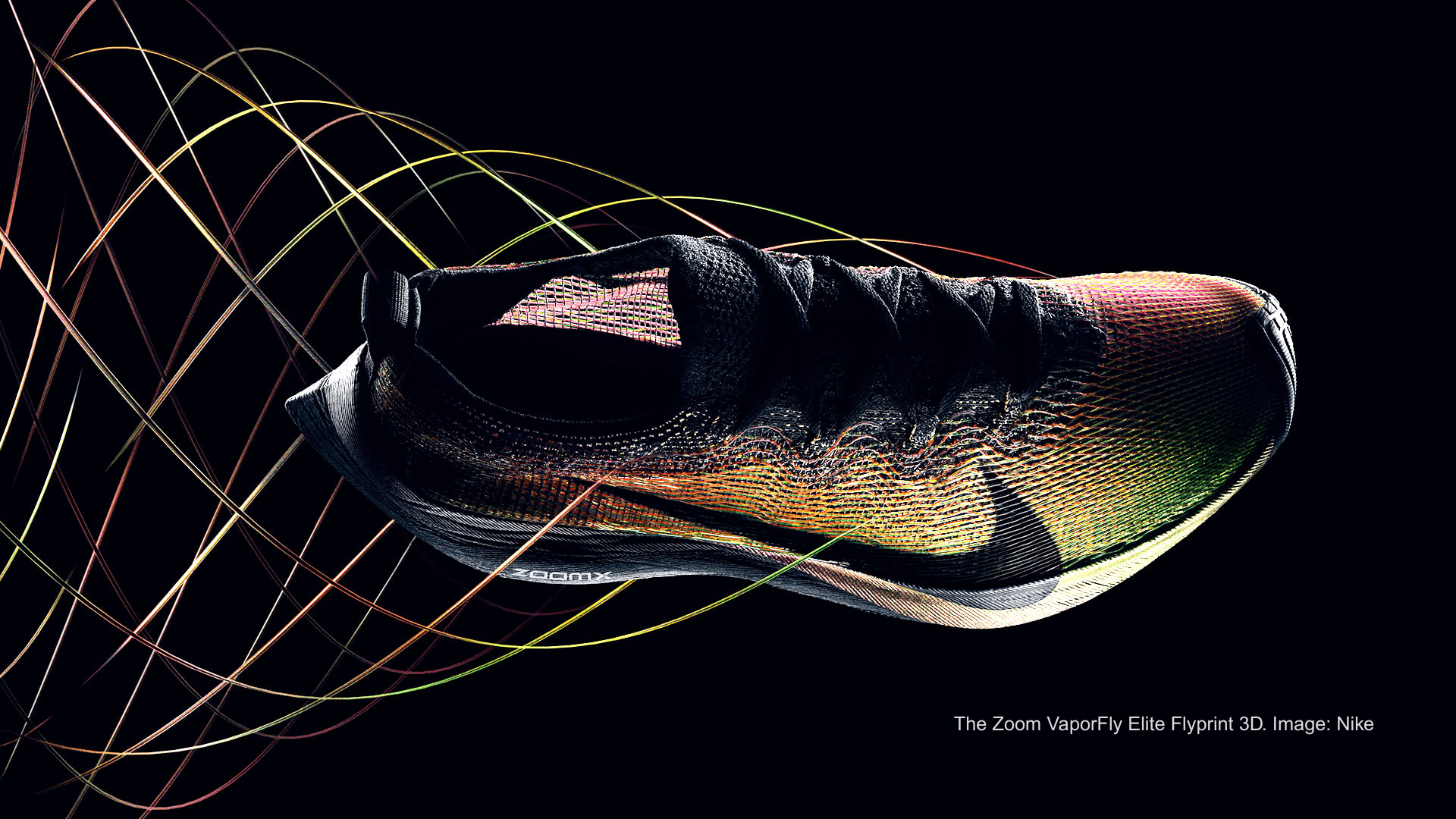

Polyurethane, which has been a longstanding contributor to modern footwear through midsoles and cushioning, has emerged as the cornerstone of a new trend in shoe manufacturing. Thanks to advances in 3D printing, global brands and startups are using polyurethane to create sustainable, customizable, and high-performance shoes.

Polyurethane’s inherent versatility allows it to be moulded into complex lattice structures with exacting precision, enabling the production of personalized shoes tailored to individual foot contours and performance needs.

A recent analysis by LuxCreo, an expert in 3D printing manufacturing, highlighted that polyurethane-based 3D printed midsoles can endure over one million heel strikes, far surpassing the wear performance of conventional EVA foams. In parallel, its recyclable properties and waste-minimizing capabilities underscore its potential to anchor a more circular economy in the fashion and sportswear industries.

Beyond performance and personalization, the appeal of PU-based 3D printing lies in its efficiency. Traditional shoe production can involve complex assembly lines and material waste. In contrast, additive manufacturing with polyurethane can allow for rapid prototyping and localized production, eliminating the need for overseas supply chains and reducing both cost and carbon footprint.

For example, Swiss performance brand On is pushing new boundaries with the Cloudboom Strike LS, a sneaker whose TPU upper is robot-sprayed in under six minutes. This high-speed automation reportedly reduces the manufacturing footprint by up to 75%.

On Cloudboom Strike LS “White/Flame”

The convergence of polyurethane chemistry and 3D printing technology signals more than just a new chapter for athletic wear, it represents a fundamental shift in industrial design philosophy. Where once mass production required compromise on fit and waste, the future now offers products that are made to measure, high performance, and ecologically sound.

As sustainability pressures mount and consumer preferences tilt toward individuality, polyurethane’s role in 3D printing may become less of a niche innovation and more of a manufacturing norm. From elite athletics to everyday sneakers, polyurethane is stepping up to redefine the very fabric of footwear.

You can learn more about this topic here.